Can We Pump The Brakes On Pumps?

Me: “I’m writing an article about pumps.”

Husband: “Bike pumps?”

Me: “No.”

Husband: “Breast pumps?”

Me: “No.”

Husband: “Gas pumps?”

Me: “No.”

Husband: “Like the high heels?”

Me: “No!” (I grabbed a hand soap bottle from our bathroom to make my point.)

Out of all the types of pumps, the liquid dispenser pump is by far the most common in our home. I did a quick count, and there are 17 in our kitchen and bathroom, that’s far more than the number of high-heel shoes I have. It goes to show that pumps are everywhere, even if they don’t really register with most people.

You may be wondering why someone would be spending time thinking about pumps—enough time, in fact, to dedicate an entire article to them. Pumps, ingenious mechanisms for controlled actuation of liquid formulas, are so functional and ubiquitous in personal care products that they’ve become interwoven with our lives. But, if you’re a packaging designer or beauty entrepreneur focused on sustainability, pumps’ pervasiveness means they’re a huge problem to tackle.

The Problem with Pumps

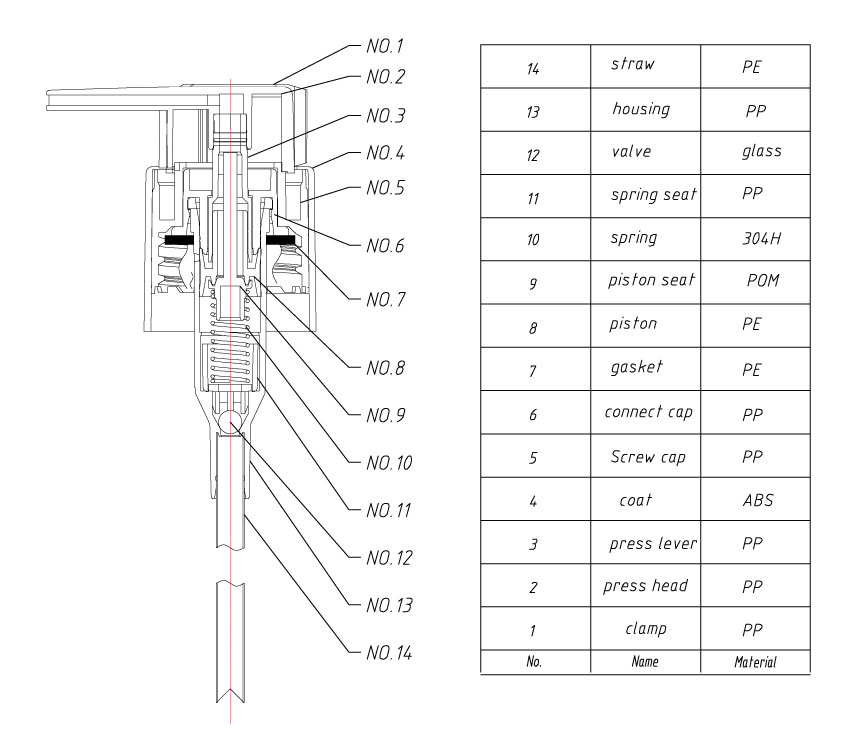

The issue isn’t so much the pump itself, but the way they’re used in consumer packaged goods. Pumps are wonderful and complex devices. A standard pump utilizes at least two to four different types of plastic, plus stainless steel, and sometimes glass and rubber. Each part of a pump is tiny and carefully crafted to do its job.

Why so many different materials? Because each part has been optimized for its unique purpose. Certain parts require a plastic with low reactability to liquid formulas to avoid stoking compatibility issues. Certain parts require a plastic that can slide against other parts with little friction. Certain parts require a plastic that can easily be pigmented to generate colors brands desire.

Don’t get me wrong—pumps do a fabulous job of dispensing the exact amount of liquid needed. The big issue with pumps is that, in most cases, they’re only used for a very short period of time before they’re tossed into the trash or recycling bin.

PUMP Recycling PREDICAMENTS

Remember the plethora of materials in pumps? Even if each individual material is recyclable, a pump would need to be dutifully disassembled and each material sorted by type to facilitate recycling. Unfortunately, since the pieces are small, they aren’t economically viable to recycle at a municipal sorting facility. As a result, the vast majority of pumps are destined for landfills.

TerraCycle, the self-proclaimed global leader in recycling hard-to-recycle materials, handles the minority of pumps that are recycled. Brands can pay TerraCycle to operate take-back programs that collect empty packages for recycling. Because brands pay for these services, there’s an economic incentive for the complicated process of disassembly and material sorting. TerraCycle’s process for recycling pumps involves shredding the pump and, then, separating out the stainless steel, plastic, glass and rubber to place into distinct recycling streams.

I spoke to a representative from Loop about how it deals with pumps. Part of TerraCycle, Loop is a circular retail platform selling household products in durable packages that customers use and return to be sanitized, refilled and resold. I was disappointed to hear that Loop doesn’t reuse pumps, probably because it’s too difficult to fully sterilize the interior cavities. The pumps are sent to TerraCycle for recycling. Perhaps in the future, Loop will design a reusable, cleanable alternative or allow consumers to purchase products with or without pumps to provide them the option of reusing a pump from a previous purchase.

Pump Alternatives

The next logical question is: Can we simply phase out pumps? After all, there are lots of other types of packages that hold liquids, including jars, tubes, squeeze bottles and droppers. And there are ways to formulate products in solid formats that don’t necessitate the amount of packaging liquid products necessitate. Those ideas are worthwhile and will work in several scenarios.

However, there are instances when a pump is truly the only option. For example, some skincare products with active ingredients use special airless containers to help prevent formulas from coming into contact with the outside environment and stave off bacteria. Another example is liquid products that are meant to be sprayed. A sprayers and atomizers are versions of pumps, and have the mixed materials and tiny parts associated with other personal care pumps.

THe REINVENTION OF PUMPS

Another approach to the pump problem is to redesign the pump for recyclability. Ren Clean Skincare is the first personal care brand to try. The brand developed a spring-free, all-plastic pump. The pump is an exciting innovation and step in the right direction. The catch is Ren’s pump contains a variety of types of plastic and recycling it remains tricky.

Brazilian packaging manufacturer Wista Airless Systems is behind a mono-material pump designed out of polyethylene or PE and has a PE spring. The tubes or bottles attached to the pumps are also constructed from PE, making the entire package 100% PE and truly mono-material. Wista offers recyclable sugarcane-based PE, too, which lessens environmental impacts by not being petroleum-based. INNBeauty Project uses a CTK Cosmetics mono-material pump in its Slushy Serum Moisturizer Cream. In an Instagram post, the clean beauty brand asserts it’s the first fully curb-side recyclable pump on the market. The pump is made from polypropylene or PP.

The next hurdle is ensuring recyclable packages actually are recycled. Brands with mono-material pumps must educate consumers to deposit packages into the right bins when they’re finished with their products. Then, the robots and people sorting items at material recovery facilities, where curbside recycling is taken before being sorted, baled and sold, have to know which pumps and packages are mono-material.

Currently, most material sorting at facilities is done visually, so a mono-material pump would get pulled off the recycling line and sent into the landfill stream since it looks like any other pump. To create identifiable recyclable pumps, a universal symbol to indicate mono-materiality should be displayed on packages. I also hope that recycling infrastructure continues to improve and innovate to introduce new ways of plastic sorting.

Pump ReUSE

Since there isn’t a great solution for recycling pumps yet, the best short-term solution is to change how we use them. The idea of throwing away a pump every time you complete your shampoo or body lotion is bananas. The fine pieces of pump machinery have the capacity to be used over and over again. Ask the brands you love to sell bottles with and without pumps included, so you have the option to reuse them. Or request brands offer refill pouches or stations to refill bottles. Try shopping for personal care items at a package-free shop. Refill the bottles in your home whenever possible instead of buying new bottles.

Eco-conscious people and companies are addressing the implications of the enormous flood of personal care plastic waste. Fortunately, they seem to agree on two things: 1). Brands have a responsibility to be thoughtful about the types of packages they put into the world. 2). Consumers should reexamine the manner in which they buy, use and discard packages, and support brands that are doing better for the earth. Together, we can find a new path for pumps.

Lauren Golik is the art director at Bartlett Brands, an award-winning boutique branding agency in San Francisco. She leverages brand strategy to create holistic visual brand narratives incorporating identity, packaging, photography, video and marketing campaigns for clients ranging from cosmetics to consumables. Prior to Bartlett Brands, Golik worked in graphic design at Kendo Brands and Bare Escentuals.

Leave a Reply

You must be logged in to post a comment.